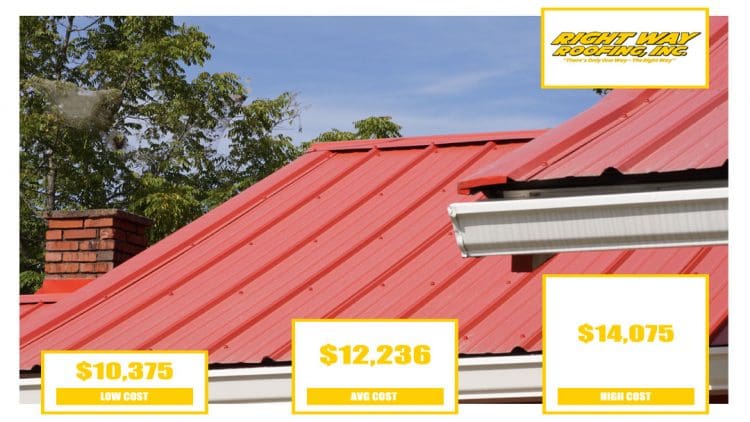

Metal roof installation costs about $12,236 with average prices ranging from $10,375 to $14,075 in Arizona according to Angieslist.com.

At the end of the day, having a metal roof installed can be less costly than an ordinary asphalt shingle roof. Metal roofs can last a lifetime, a lot have a modern look, and they save big money on your energy bills by keeping your house cooler during the scorching months.

Why are Metal Roofs More Expensive?

Here is Why a Metal Roof Will Cost More:

- They typically last a lifetime, although a lot have warranties for a meager 50 years. Asphalt shingle roofing usually needs to be replaced every 25 years, so spending more money firsthand on a metal roof can save you over time.

- They are pretty much maintenance-free. You will save on maintenance costs.

- They are significantly durable. Metal roofs can weather intense environmental elements.

Think about choosing aluminum or steel roofing material rather than the more expensive metals: zinc and copper.

Warranty and Savings on Energy

Verify with the roofing contractor about a roofing warranty, as many companies can charge up to $3,000 additionally for one. Nonetheless, having a roofing guarantee is worth the money.

Installing a metal roof can help you save up to 40% on your cooling costs as opposed to asphalt shingles. Why is that? Metal roofing reflects sunlight, so your attic and general roof temperatures will be reduced. As a result, helping you save on cooling costs throughout hotter months.

Many homeowners even had their insurance rates reduced after getting a metal roof installed.

Find a Roofing Contractor in Payson

Make sure to ask about a lot of estimates from trained roofing contractors that have experience installing metal roofs. Roofing contractors frequently require a trade license, so be sure to ask roofing contractors about their city and/or state licenses if they are required in your region. They’ll also be required to pull any building permits.

Advantages of Metal Roofing in Payson

Metal roofs are a common roofing technique. It’s a little more costly than roof shingles. Metal roofs can last a lifetime and they demonstrate to be better at the end of the day. Metal roofs have a straightforward but elegant look. Metal roofs keep homes cool in the summer months saving on energy bills of upwards of 40% of the yearly energy costs. Utilizing metal as a roofing material is more costly but has its own advantages.

Metal roofing is a long-lasting roofing system therefore quality is essential. Spending more money on high-quality metal roofing is a once in a lifetime investment. It is vital to get it right the first go around.

Metal roofing doesn’t sustain maintenance fees. There aren’t any more financial obligations after the metal roof is installed. They are manufactured to endure all weather conditions regardless if it is warm or cold.

These qualities make metal roofing distinct therefore it can be used in in a lot of geographic locations.

What is the Labor Cost for Metal Roof Installation in Payson?

Metal roof installation costs are around $5.50 per sq. ft. and $12 per sq. ft., respectively. Metal roof shingles costs from $7 per sq. ft. to -$10 per sq. ft. installed. Its going to cost from $9 per sq. ft. to $12 per sq. ft. for a standing seam metal roof installation.

For instance, if you have 1,500 sq. ft roof, the average cost of metal roof installation is $8 per square foot – it will cost you $12,000 for the installation of the metal roofing. There are affordable shingles that can be installed on the old roofs top.

The roofing contractor doing the install is going to be important when it comes to its cost. It is a good idea to get a couple of estimates prior to choosing and hiring a roofing contractor.

Will Roof Design Change The Cost in Payson, AZ?

Your roofs architectural design can add to the metal roofing installation cost. If the design is complex, has too many domes, a lot of angles, or a skylight it will need higher skills from professional roofing contractors. This is going to increase the labor costs.

Metal roofing costs are a slightly higher because it is permanent on your roof option. It is beneficial for energy savings. It is cost effective to insure a home that has a metal roof. All in all it is a cost-saving roofing solution.

Metal Roof Installation Payson, Arizona

Right Way Roofing, Inc. offers residential roof installation and commercial roof installation in Payson, Arizona and surrounding cities. If you need a new roof installed or replaced, Right Way Roofing, Inc., is the right way to go! Contact us or call us at 602-299-8851 for more information.